Deep Litter System

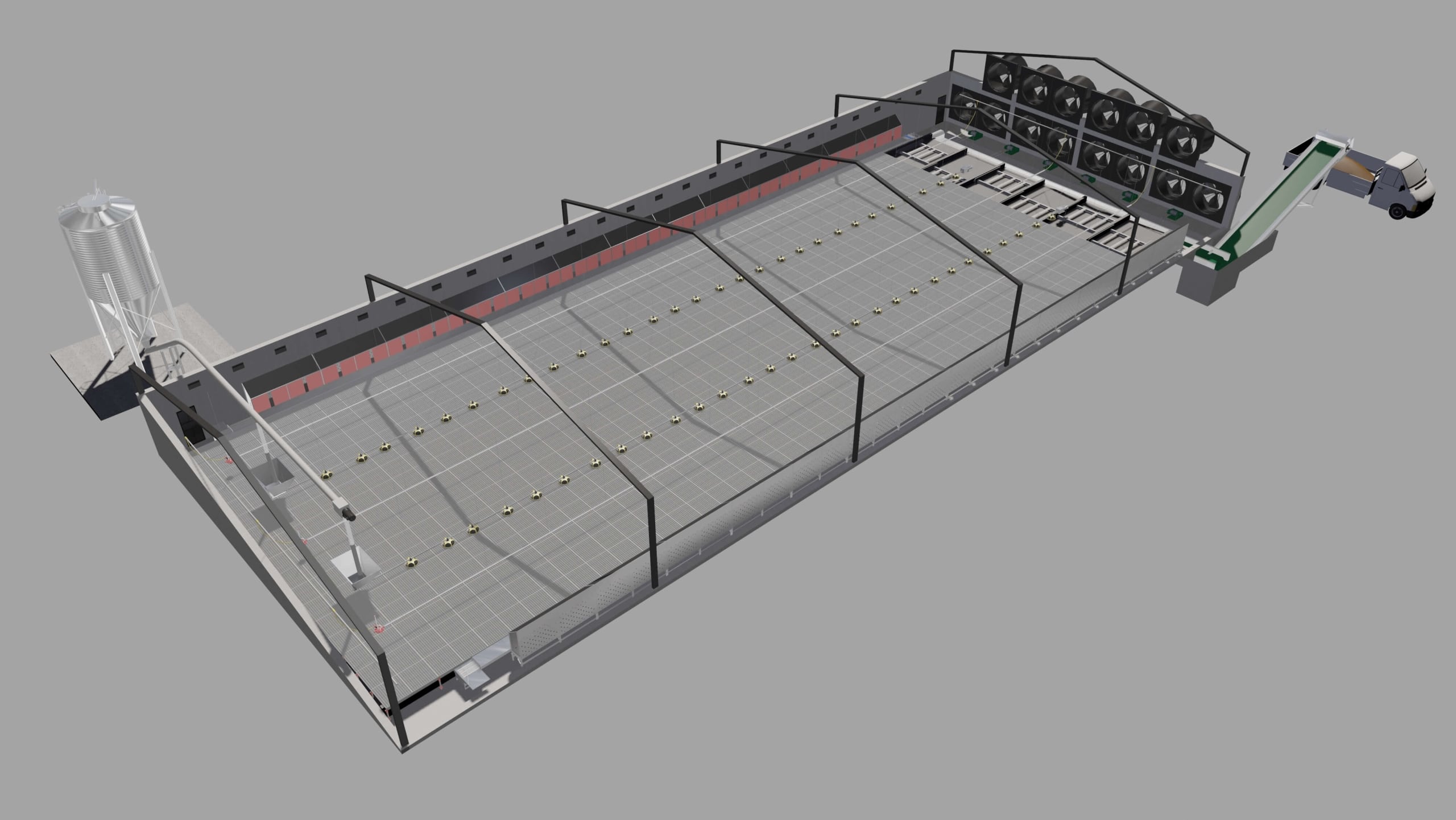

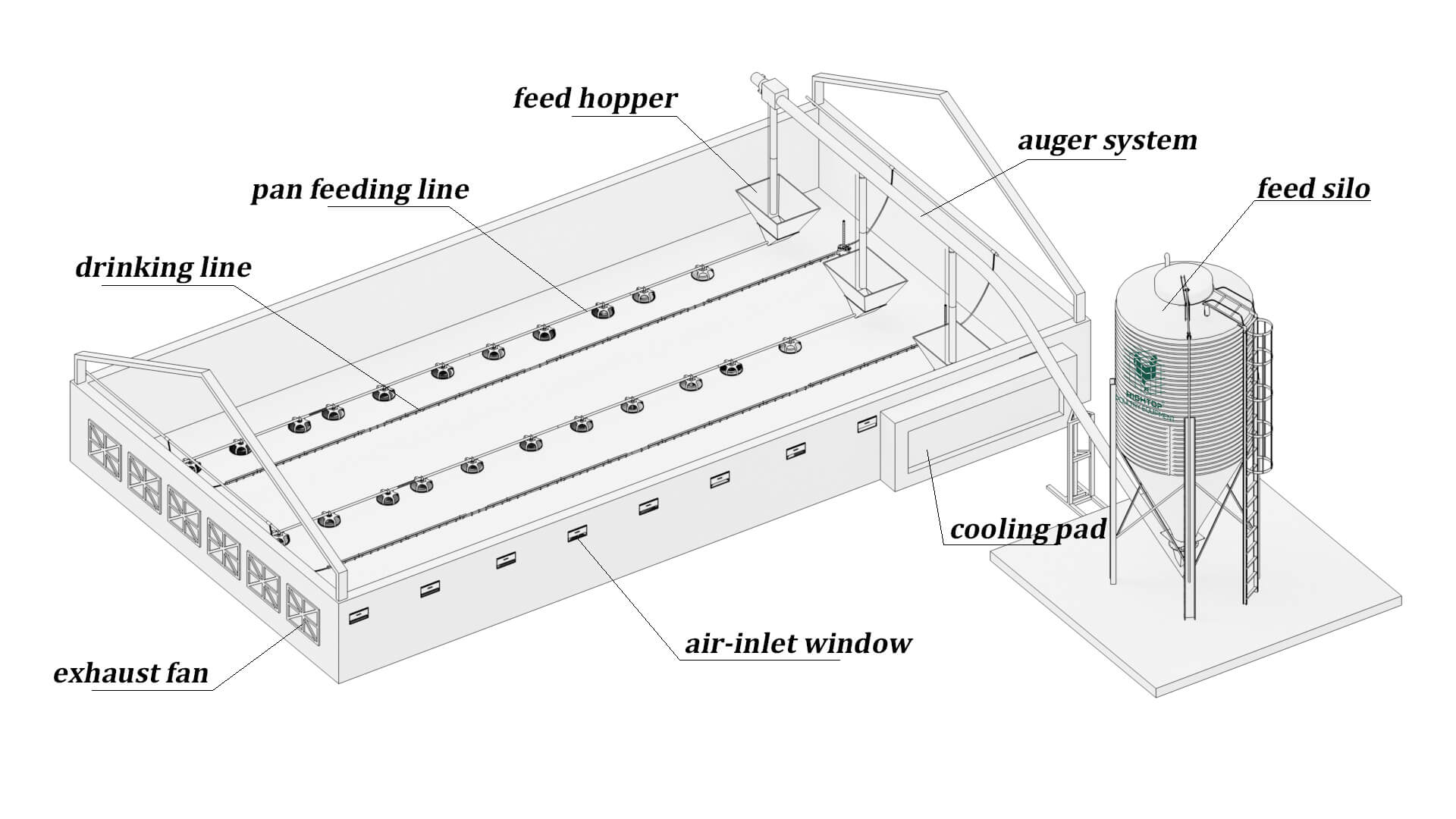

Deep Litter System, also named deep litter chicken coop consists of an Automatic Main Stock Line System, Automatic Pan Feeding System, Automatic Drinking System, Ventilation system, Environment control system, Cooling pad & heating system, providing a better living environment for broilers.

-Simple operation, save feeding time, efficient

-Generally, the height of poultry houses is between 2.5m-3.5 m (at eaves). The width of the poultry houses is decided according to the layout of equipment inside and cannot be too large considering ventilation. Steel-structure poultry houses are usually designed to have a width of 8-15m. Length is better no larger than 140m.

Recommended Chicken House Breeding Quantity

| Chicken quantity per building | Equipment type | Recommend building size |

|---|---|---|

| 5000 birds/building | 3 feed lines, 2 water lines | 45*10*3m |

| 10000 birds/building | 3 feed lines, 2 water lines | 93*10*3m |

| 15000 birds/building | 3 feed lines, 4 water lines | 85*12*3m |

| 20000 birds/building | 4 feed lines, 5 water lines | 120*15*3m |

| 25000 birds/building | 4 feed lines, 5 water lines | 138*16*3m |

Our 3D Design

Automatic System

1.Automatic Main Stock Line System

Silo

1. The silo is used for feeding system hopper.

2. Elevated feed to feeding system hopper.

3. Capacity:10 tons,15 tons,20 tons

Ground hopper

1. The equipment is used for feeding system hopper.

2.Capacity:800 KG

3.Size:1.2*1.2m

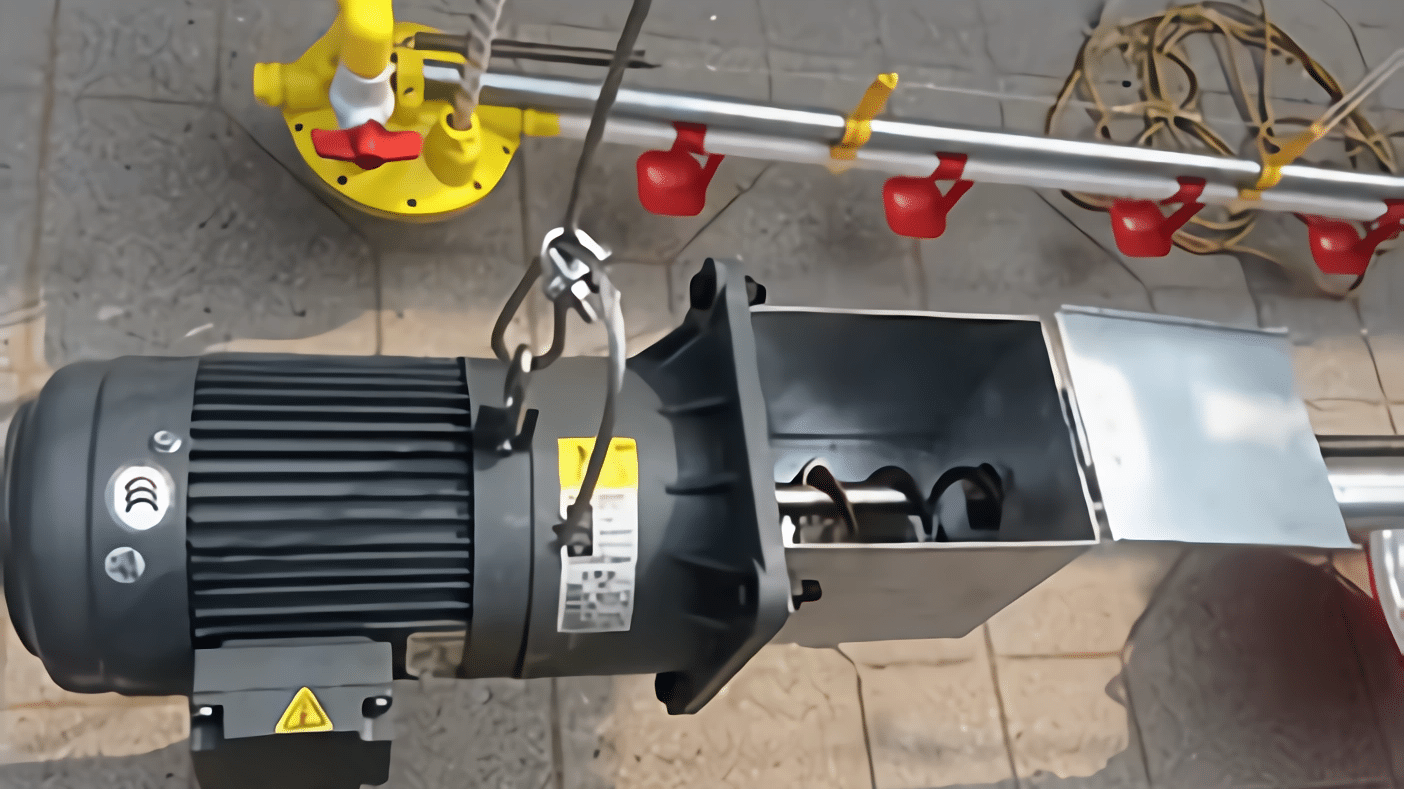

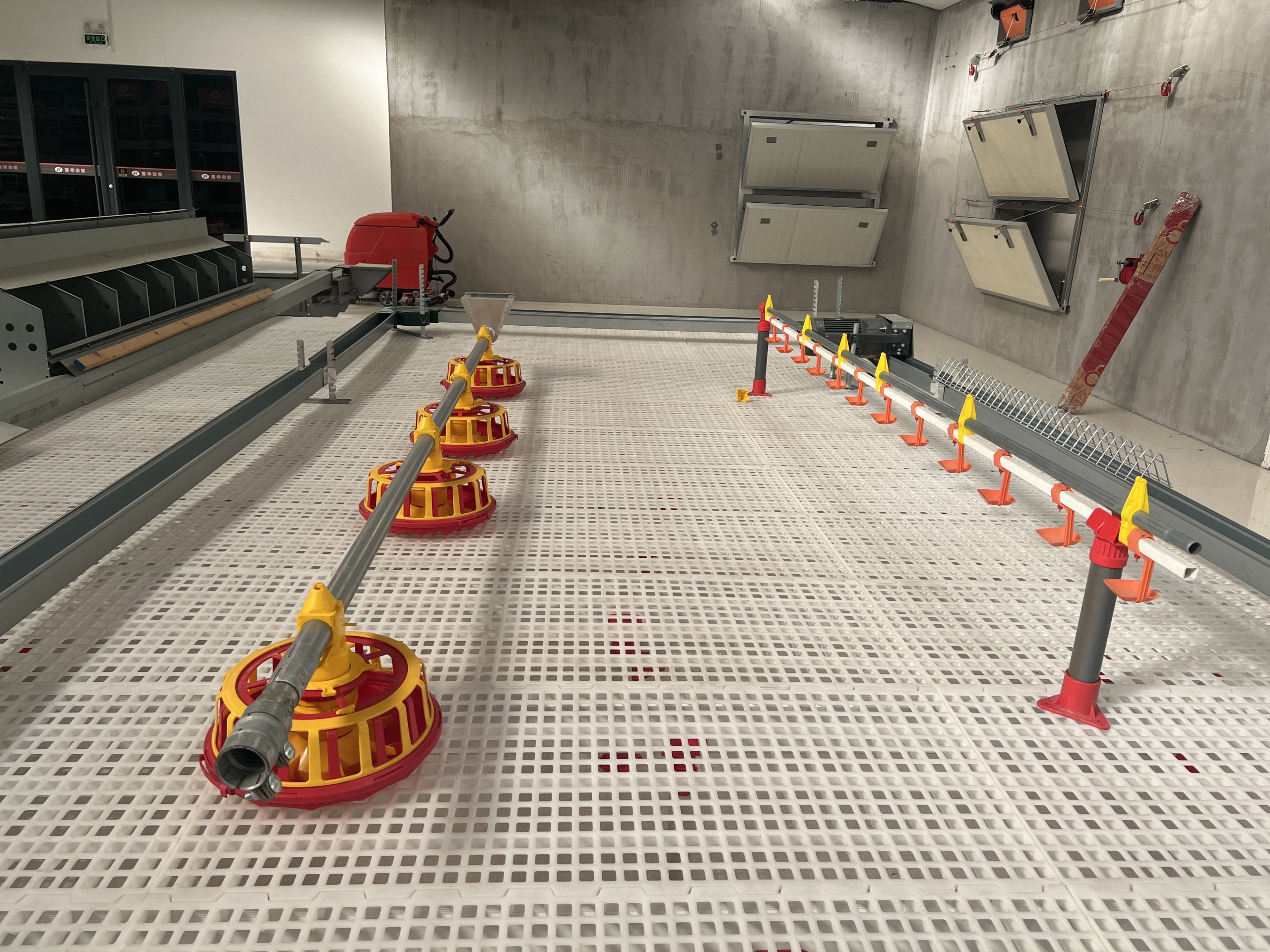

2. Automatic Pan Feeding System

Driving motor

1.0.75kw,220V,3 phase,60hz

2. Taiwan brand

Control box

1. Control pan feeding line;

2. Each pan feeding line can work independently.

Feed pipe with 4 holes

1. Material: hot-dip galvanized steel

2. Zinc coated: 275g/m2

3.Thickness:1.2mm

Feedstuff hopper

1. Material: hot galvanized steel

2.Thickness:1.2mm

3.Zinc coated:275g/m2;

4.Capacity:60 KG

Feed pan:

1. Pan diameter 330mm

2.Pan material:100% virgin PE material

3 .Pan capacity:1.5KG, It can suffice any time of rearing.

4. With anti-UV additive

5 . Feed capacity: 12 birds/pan

6. The pan bottom can be used as a starter pan

7. Pan use: starting from 1 day age

8. Cleaning: hang dry , wash by high-pressure water, easy cleaning

9. Bottom shape: wave-shape bottom and flat bottom are all available to choose

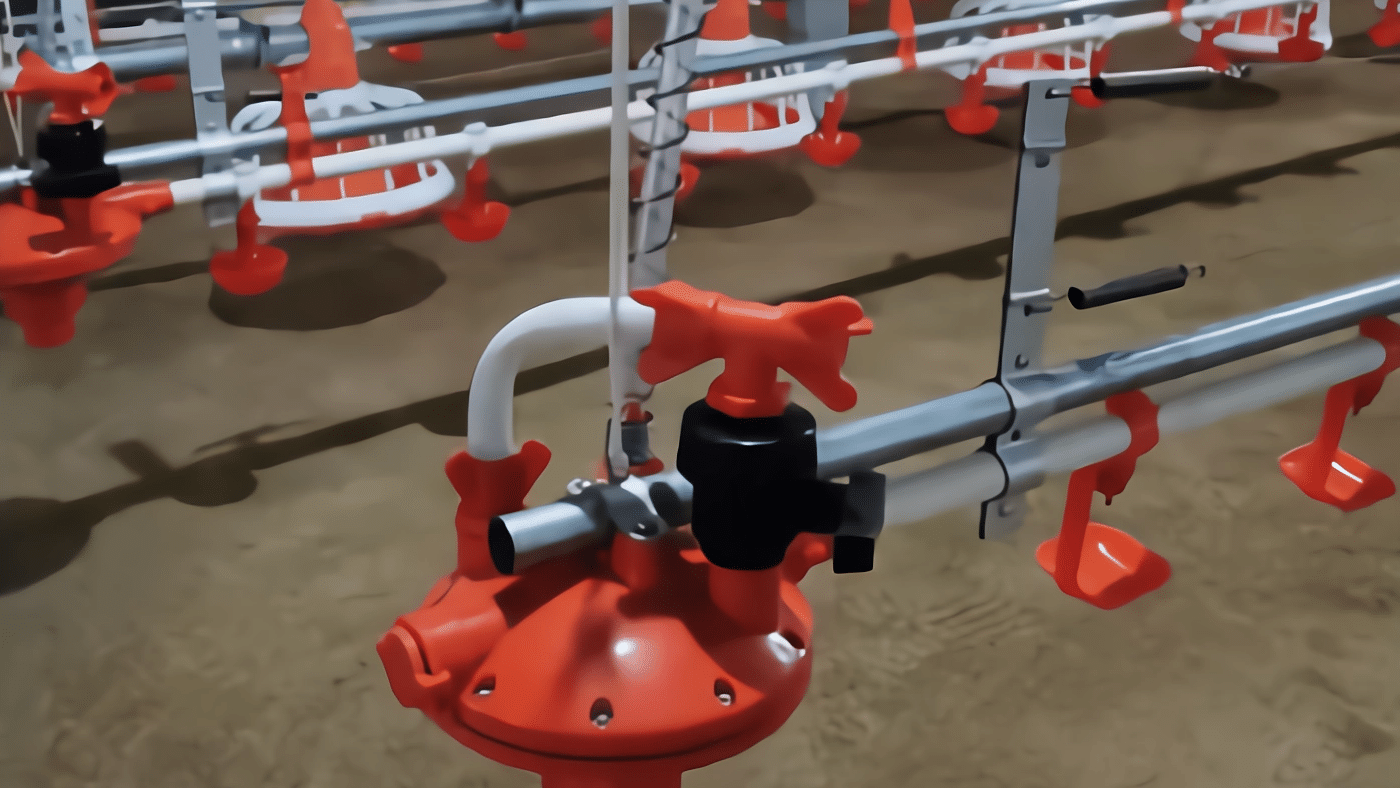

3.Automatic Drinking System

Water pipe and nipple drinker

1. The water connection is all sealed to avoid contact with air and dust, ensuring clean water and preventing water pollution

2. The drinking nipple is designed with high sensitivity, which can ensure 360-degree rotation.

3. Only the chicken peck the nipple drinker, the water will go out.

Automatic drinking system

1. Pressure regulator

2. Flexible adjust, long lifespan

4.Plastic Floor System

Plastic Floor System

1. Easy for broilers’ chicken coop manure cleaning.

2. PVC blending extrusion, smooth and clean, and burr-free.

3. Corrosion resistant,anti-aging, good design, and no waste

4. The surface width is 25mm, the gap is 11mm or 21mm, and the surface is with non-slip streaks. The size width is 500mm, and the length is 1000,1500,2000.3000mm. It can also be customized according to customers’ demands.

5. Easy maintenance, if there is something wrong, it is easy to change a new piece.

5. Environment Control System

Ventilation fan system

The ventilation fan system controls the poultry house’s inner environment, provides fresh air and proper humidity for your chickens, and ensures your broilers produce maximum production.

Cooling pad system

When the air goes through cooling pads,the heat will be taken down by the evaporation of water.So the air will be cooled before going into your poultry farms.

Environmental control equipment

The environment control system constantly monitors the environmental data of the chicken shed based on temperature and humidity sensor data. It controls the cooling fans, cooling pads, and the clear story automatically by a micro computer integrated system.

Free Range Farm Display