Estimating land requirements depends on the production system you choose. For high-density automated cage systems, the space utilization is far more efficient than with traditional free-range setups.

In a well-designed cage system, you might need as little as 0.05 to 0.1 square meters per broiler, depending on the cage configuration and local regulations. For a 10,000-broiler operation, this could mean a building footprint of roughly 500 to 1,000 square meters. However, these estimates should also include space for walkways, equipment, and service areas.

In contrast, free-range systems typically require 3 to 4 times more space due to the necessity for outdoor access and additional environmental management.

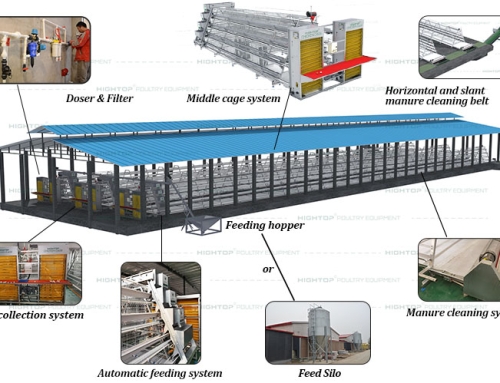

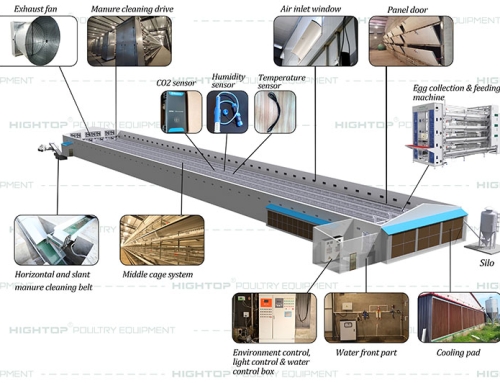

First, they significantly reduce labor costs by automating feeding, water supply, manure removal, and environmental control. Fewer manual tasks translate to lower operational expenses.

Moreover, these systems optimize feed conversion and boost overall flock productivity.

ROI can typically be expected within 3 to 5 years, as increased efficiency and lower mortality rates enhance production capacity.

Automated systems also reduce feed waste through precise dosing and uniform feeding distribution, which further cuts costs over time.

In addition, the consistent production levels achieved by maintaining a controlled environment lead to improved product quality and steady income.

Firstly, regular and thorough cleaning of the litter and coop is essential; however, in floor systems, manure management is less frequent compared to daily cleaned cage systems. This infrequency can result in a buildup of ammonia and pathogens.

Implementing strict disinfection protocols, scheduled deep cleans between flocks, and ensuring proper ventilation is critical.

Maintaining a lower stocking density can help reduce disease transmission among birds.

It’s also vital to monitor the flock regularly and isolate any sick birds to prevent outbreaks.

Integrating automated systems can indirectly aid in reducing disease by ensuring a stable environment and reducing human error.

Hightop Poultry Equipment is a factory with automatic production machines. We can show you a video of the machines working. We only need two weeks to prepare the goods ordered.

We have a lot of customers in Africa and Asia, including the Philippines, Uganda, Nigeria, Tanzania, Ghana, Zambia, Cameroon, Mozambique, South Africa, Senegal, Kenya, Zimbabwe, Malawi, Guyana, Gambia, and Equatorial Guinea. You can go and visit customers’ farms to check the quality of our products. We also have ISO certification, Soncap certification, PVOC certification, neutral salt spray test and so on.

We can produce 3-5 tier cages with 90, 96, or 120 chickens in one 3-tier cage; 120, 128, or 160 chickens in one 4-tier cage; and 150, 160, or 200 chicken in one 5-tier cage.

We can recommend the right type of cages according to the size of your chicken house, as well as the quantity and weight of your chickens.

The MOQ is 10 sets, one 20′ general purpose (GP) container can hold 130 sets 3-tier cages, or 100 sets 4-tier cages. A 40′ GP container can hold 280 sets 3-tier cages, or 210 sets 4-tier cages. A 40 high cube (HC) container can hold 300 sets 3-tier cages, or 225 sets 4-tier cages.

It depends on the type. Electric galvanized cages have a lifespan of about 7-10 years and hot-dipped galvanized about 15-20 years.

If you order less container load (LCL) we pack in a wooden box. If you order a full container we pack in bulk.

5 days after the prepayment if we have stock, or 20 days after prepayment if we need to produce. We usually have 600 sets in stock.

TT or electronic transfer, PayPal, Western Union, MoneyGram

30 percent prepayment is required and the balance of 70 percent before loading.

- Lagos Full container: 45 days; LCL 65 days

- Mombasa Full container: 25-43 days; LCL 45 days

- Tema Full container: 50 days

- Philippines

- Cebu, Full container: 12-14 days; LCL 25 days

- Manila, Full container: 12-14 days; LCL 12 or 25 days

- Davao, Full container: 25 days

- Dar es Salaam Full container: 38 days; LCL: 50 days

- Durban Full container: 30 days

- Maputo Full container: 36 days

- Djibouti port LCL: 55 days

We offer two installation instruction options:

- We can provide with an installation video

- We can send an engineer to your farm

We will change the accessories if they are damaged within two years.