Hello, everyone. Today I would like to introduce our new project in the Philippines. This customer purchased an ordinary cage from our company for the first time in October 2023, expanded the original chicken house to 20,000, and built a new H-type automation equipment in January this year. That is, the project introduced to you below.

Project Details:

This customer originally purchased ordinary cages from us, with a total breeding number of 20,000. At present, a new chicken house of H-type automatic cages for 30,000 layers has been expanded.

Why did he invest in H automatic equipment so quickly?

The current egg market has a good prospect. Eggs are the cheapest nutritional product. Basically, everyone eats an egg every day, and the demand is very large. The Philippines had a population of 117 million in 2023, and basically, 100 million eggs are needed every day. Eggs are consumables, and this demand will not decrease.

The recent egg price is also very good and has increased by 30%. So the current investment is for greater benefits in the future.

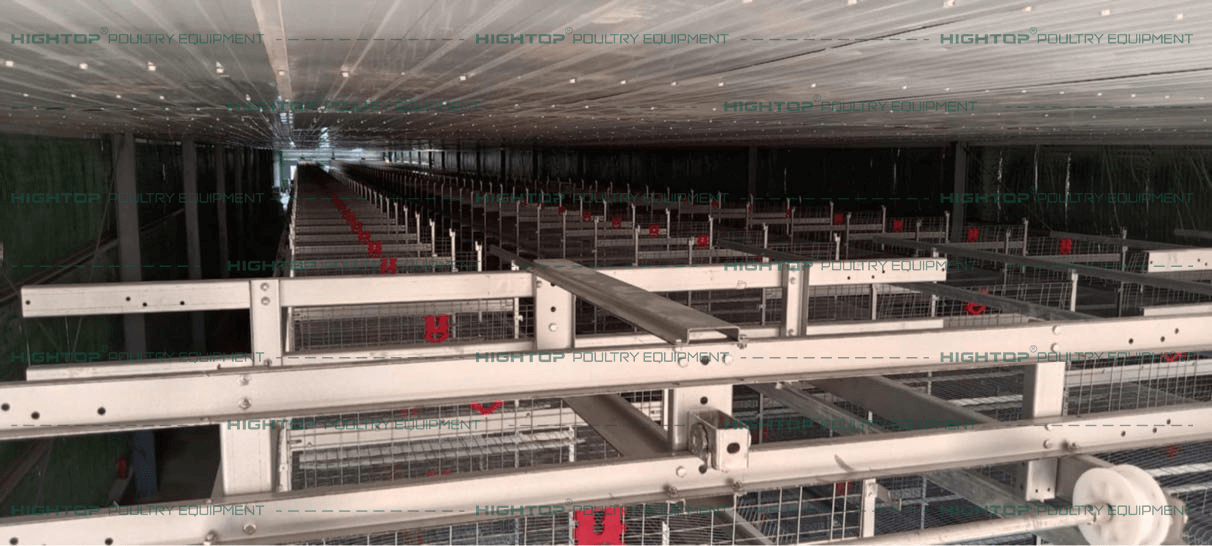

An H-type automatic layer cage can achieve the goal of raising more laying hens on the same area of land and maximize the use of land.

When others can raise 15,600 laying hens with free-range equipment on 1,040 square meters of land and 22,080 laying hens with ordinary cages, this customer, who is using H-type fully automatic equipment can raise twice as many as them, so the income will also be twice as much as theirs, that is, he can earn two years’ money in one year, which is why many people are willing to invest in automatic equipment for their farms: although investment is required in the early stage, the income in the later stage is doubled. When your farm develops faster than others’ farms, you can seize the market faster.

At the same time, with the automated feeding, watering, and egg collection systems, farm owners can spend less time tending to their chickens and more time focusing on other aspects of their operation. This can lead to increased productivity and profitability in the long run.

And the efficiency of the machine will be higher. For example, a farm with 30,000 laying hens in ordinary cages will need about 8-9 people to take care of it, and it will take about 3 hours to feed it, but for an automatic equipment farm, only 1-2 people will be needed to take care of it, and it will only take half an hour to feed it. After all, people get tired and their efficiency decreases, but machines don’t. As long as you press the switch, they will continue to work at a high efficiency.

Whether you are interested in raising chickens, want to start your poultry farming business, or want to upgrade your farm, we can provide you with customized services. Welcome to consult us.