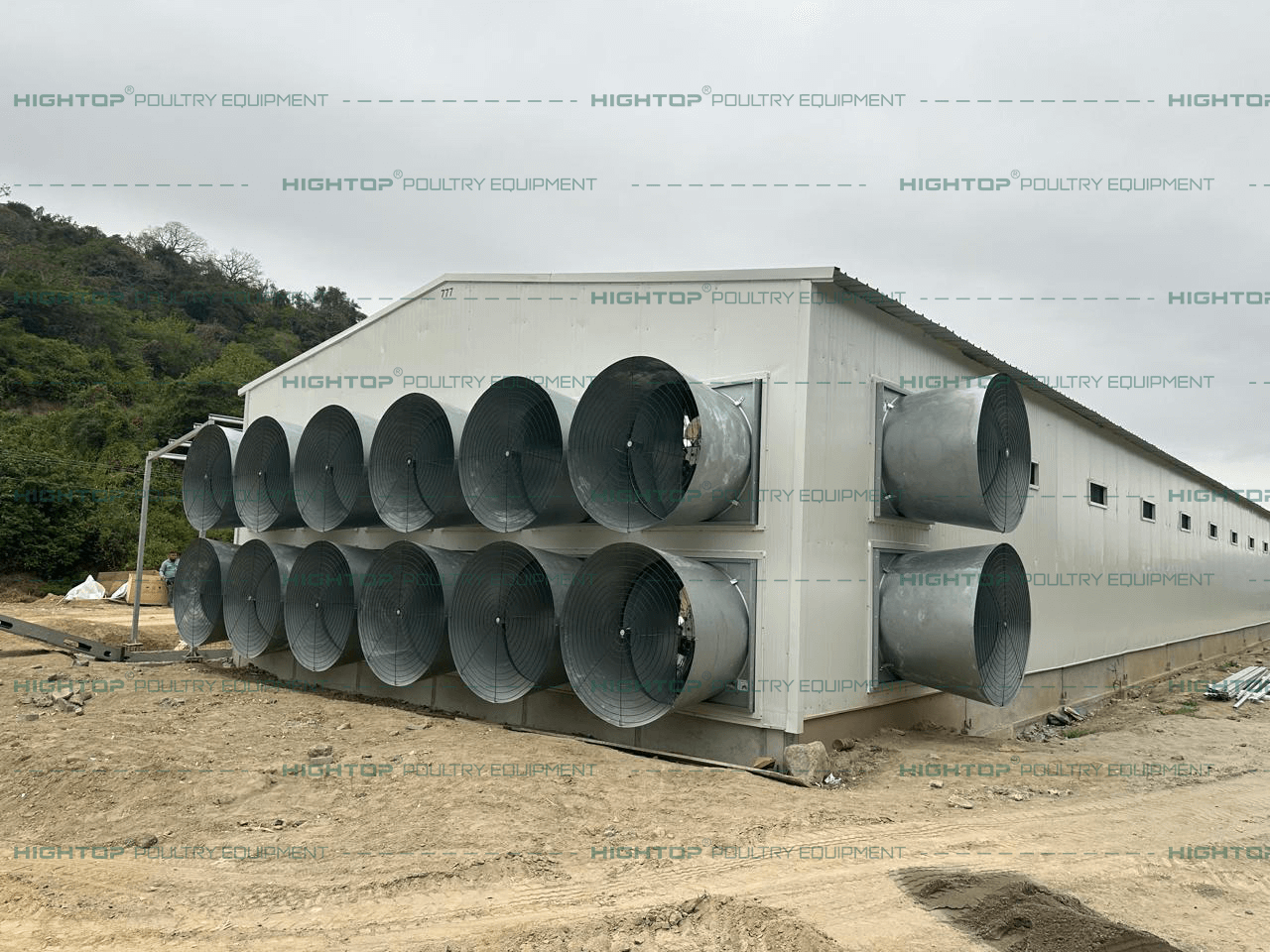

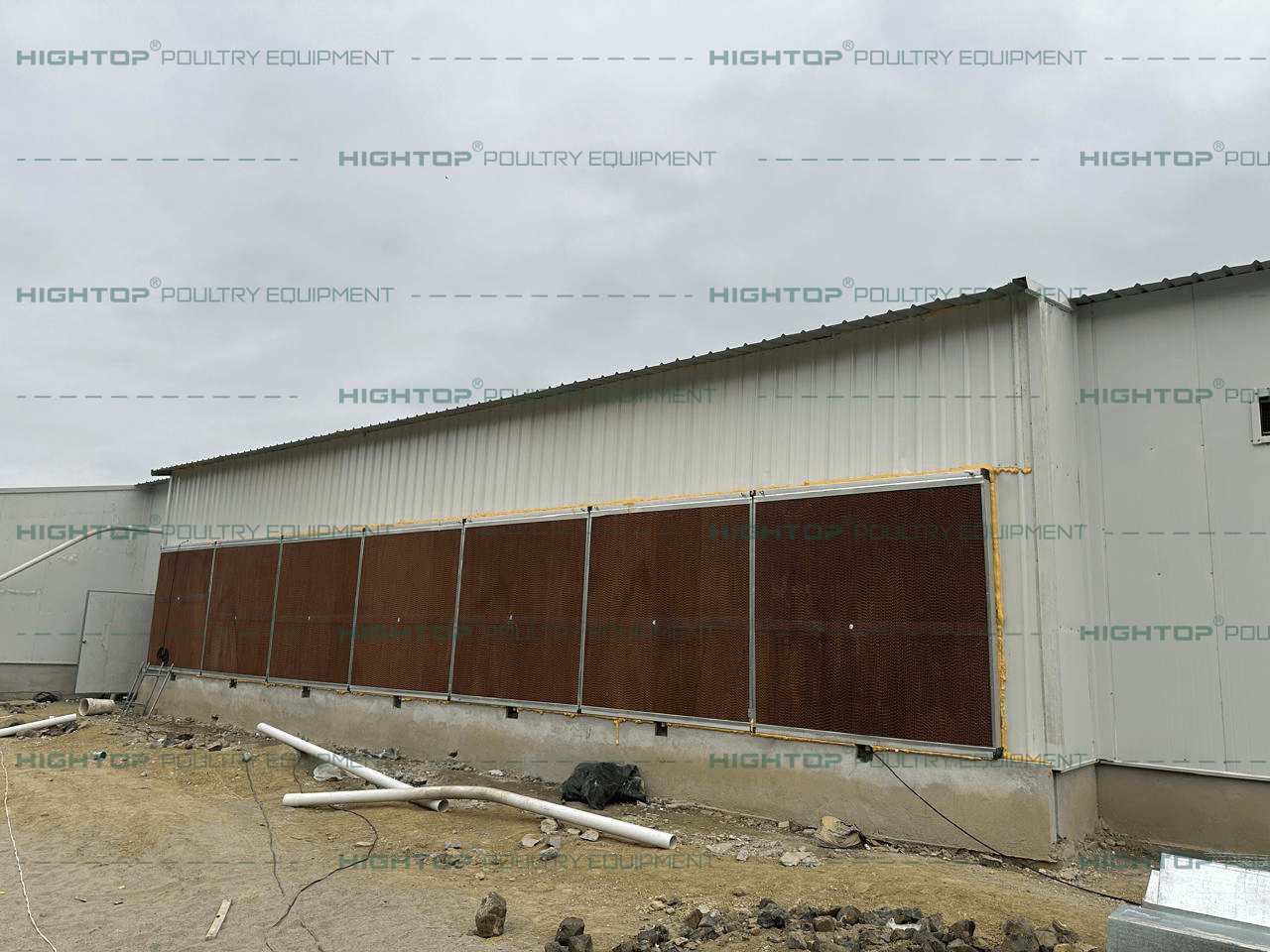

In June 2024, our client in Guayaquil, Ecuador, successfully implemented Hightop Poultry Cage’s H Type automatic layer chicken cages combined with a prefab steel structure chicken house. The project accommodates 30,000 birds per shed, showcasing the scalability and efficiency of our poultry equipment.

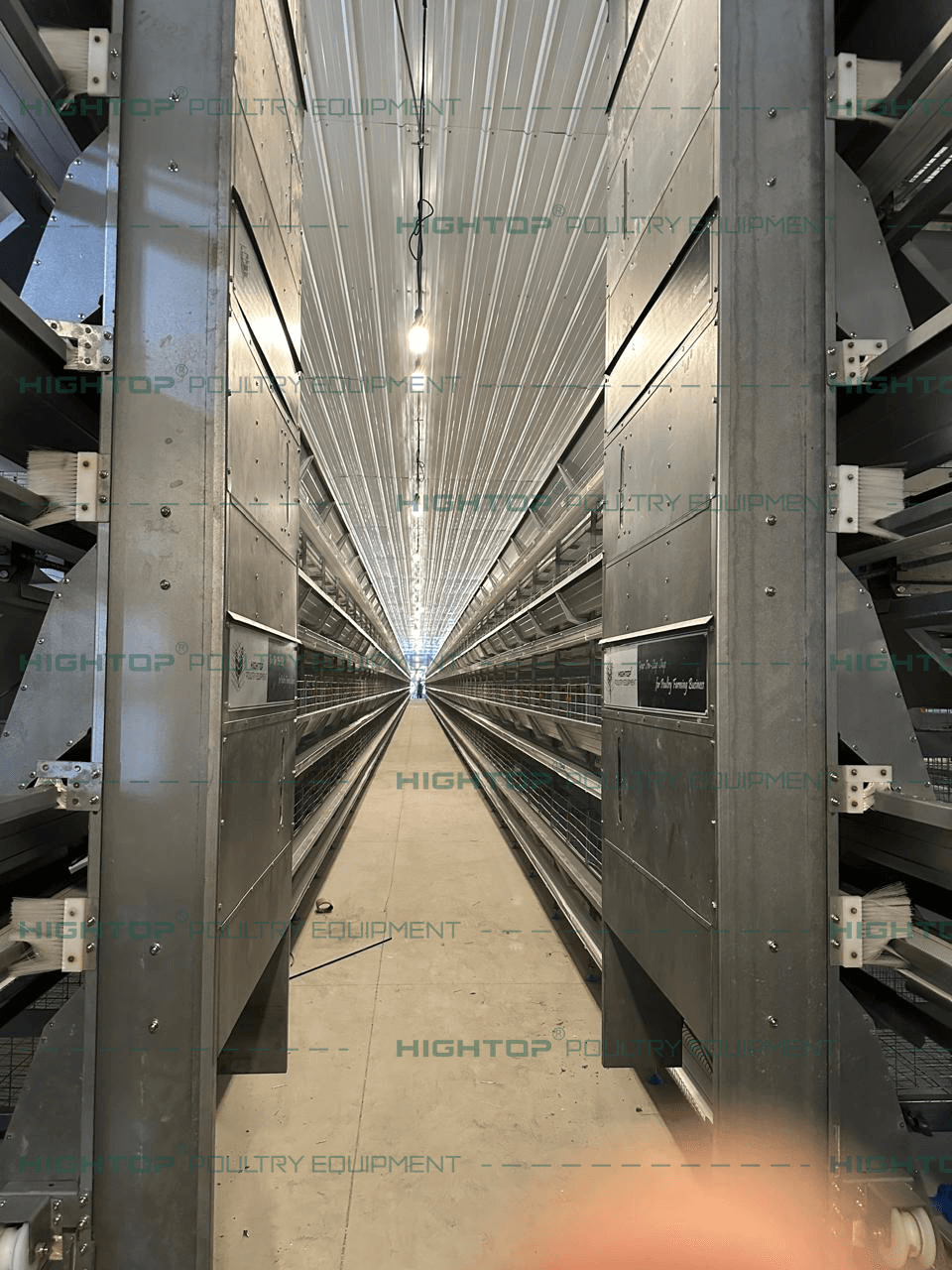

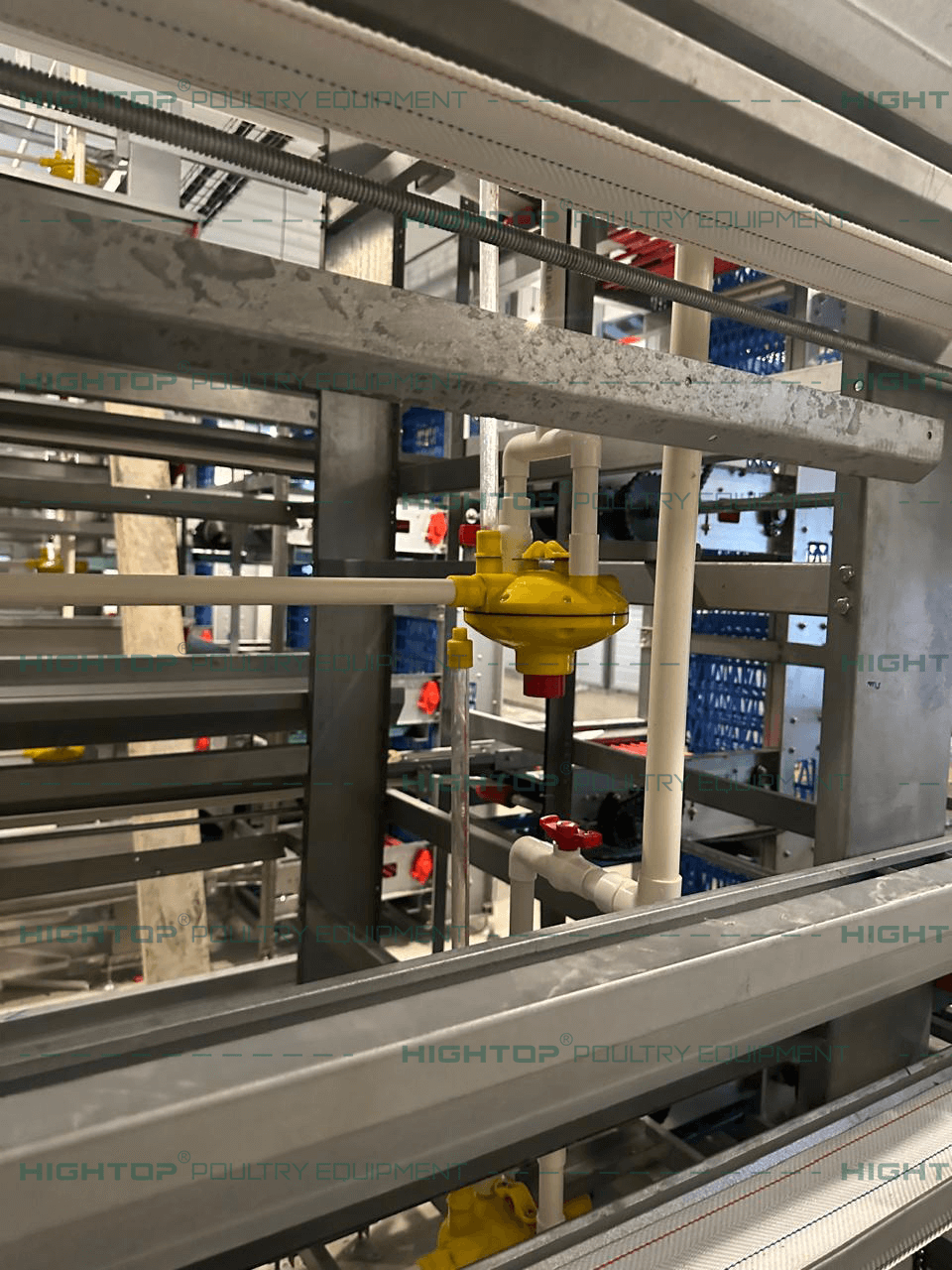

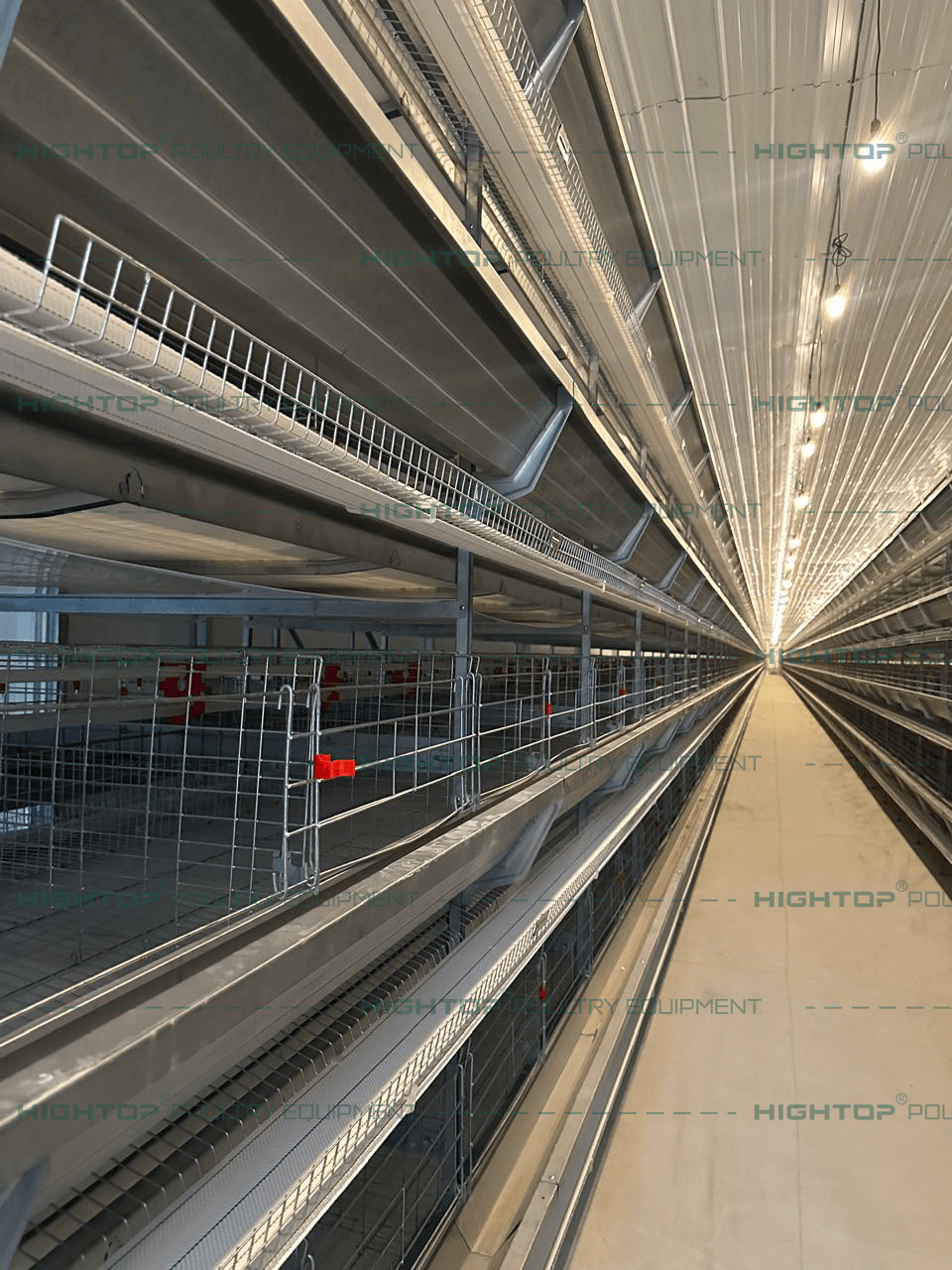

The chicken house, with dimensions of 104×10.2×4.0m, was specifically designed to optimize space and ensure maximum productivity. The shed is equipped with 3 rows and 4 tiers of layer chicken cages, enabling efficient use of the building’s area. This system integrates key automatic solutions, including the automatic feeding system, automatic drinking water system, automatic manure cleaning system, automatic egg collection system, and environmental control system. These advanced features work seamlessly together to streamline operations, reduce labor intensity, and improve production efficiency.

Our client expressed great satisfaction with the automated poultry equipment and prefab steel structure. The H-Type automatic equipment ensures consistent egg production while maintaining a clean and healthy environment for the birds. By adopting Hightop’s complete solution, the farm in Guayaquil has optimized resource usage and reduced operational costs, marking it as a modern, highly efficient poultry farming facility.

This successful collaboration highlights Hightop Poultry Cage’s ability to deliver turnkey solutions tailored to large-scale farms worldwide, ensuring customer satisfaction and superior performance in poultry farming.