The customer went through three purchases. The first two were purchased from two other companies, and various problems occurred. Finally, during the third purchase, our Hightop met all the customer’s requirements, solved all his problems, and received praise from the customer.

Project details:

The first chicken cage purchased by the customer had a serious quality problem: rust. The reason is that the surface treatment process of the cage is not good, the amount of zinc coating is too low, and it will rust in a short time. Some chicken cage prices look cheap, which may mean a relatively low amount of zinc coating, resulting in a short service life.

The second chicken cage purchased by the customer had serious cage design problems: the cage frame width was too narrow, resulting in overlapping cage nets. The overlapping cage nets would cause the chicken manure in the upper cage net to not fall to the ground, but to fall to the lower cage net, causing the chicken manure to accumulate on the cage. If the chicken manure is not handled in time, a large amount of ammonia will be released, which can cause diseases in chickens, thus causing the death of the chickens raised by the customer.

Because of the bad experience of purchasing chicken cages twice before, the customer was very rigorous and cautious in purchasing chicken cages this time and had high requirements for chicken cages and suppliers.

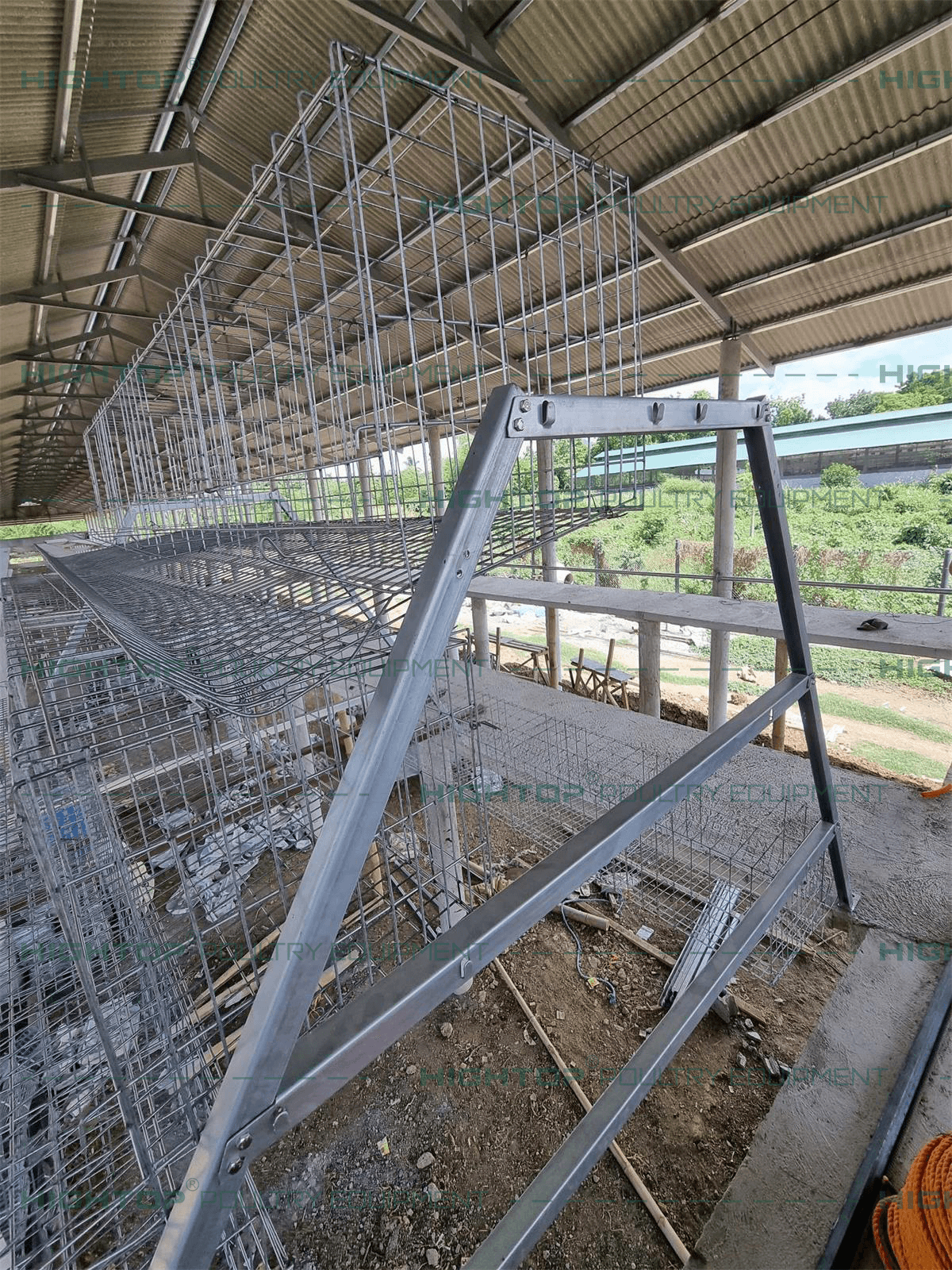

In response to the problems caused by the customer’s first two purchases, Hightop made corresponding solutions.

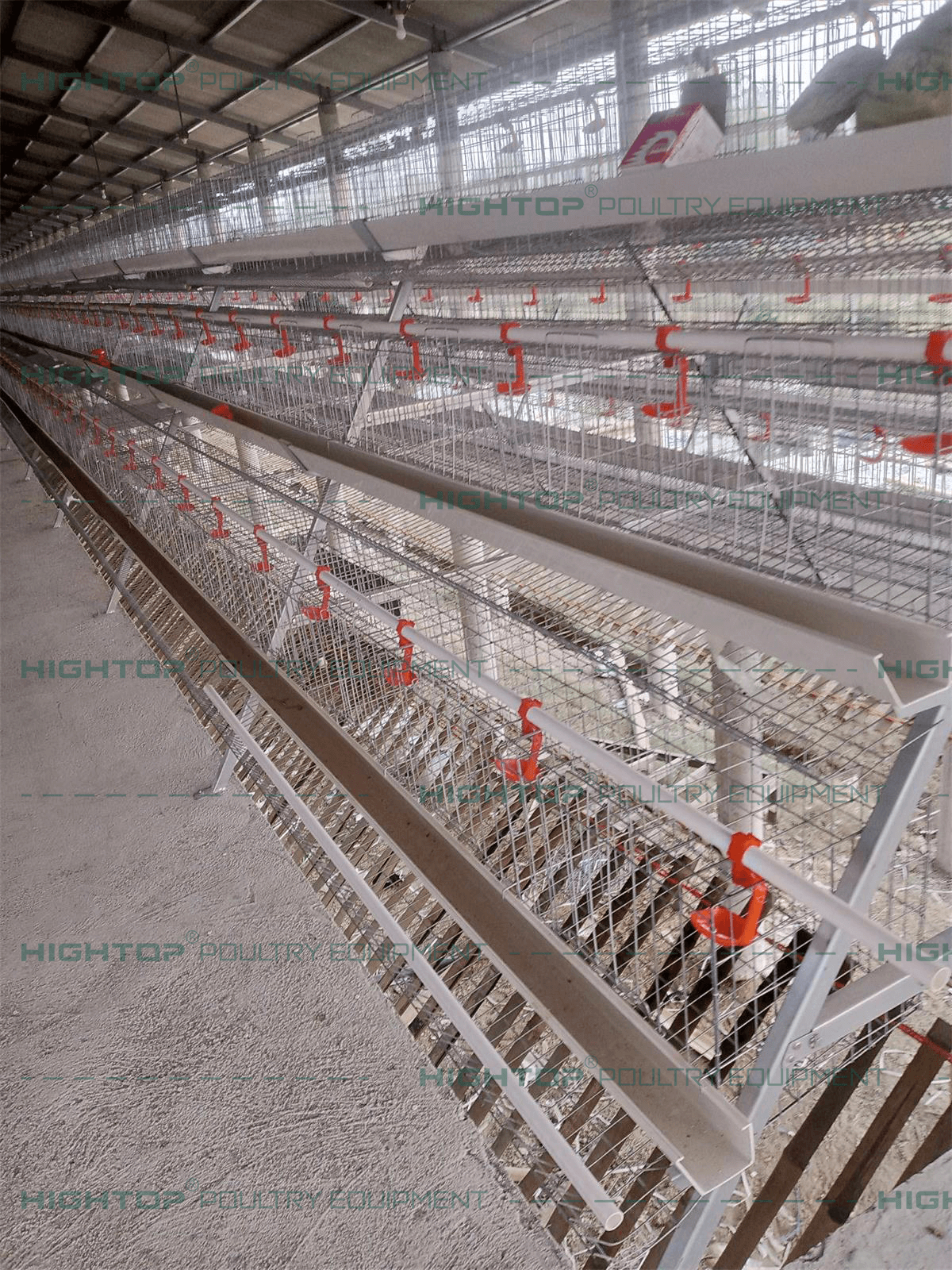

First of all, in response to the problem of rust on the chicken cages purchased by the customer for the first time, we used marine-grade cage mesh wire, zinc with a zinc content of 275g/sq.m + 10% aluminum added, which has a good anti-rust effect. Our marine-grade cages have better anti-corrosion quality than traditional galvanized cages. The service life of galvanized cages is 7-10 years, while our cages are more than 25 years.

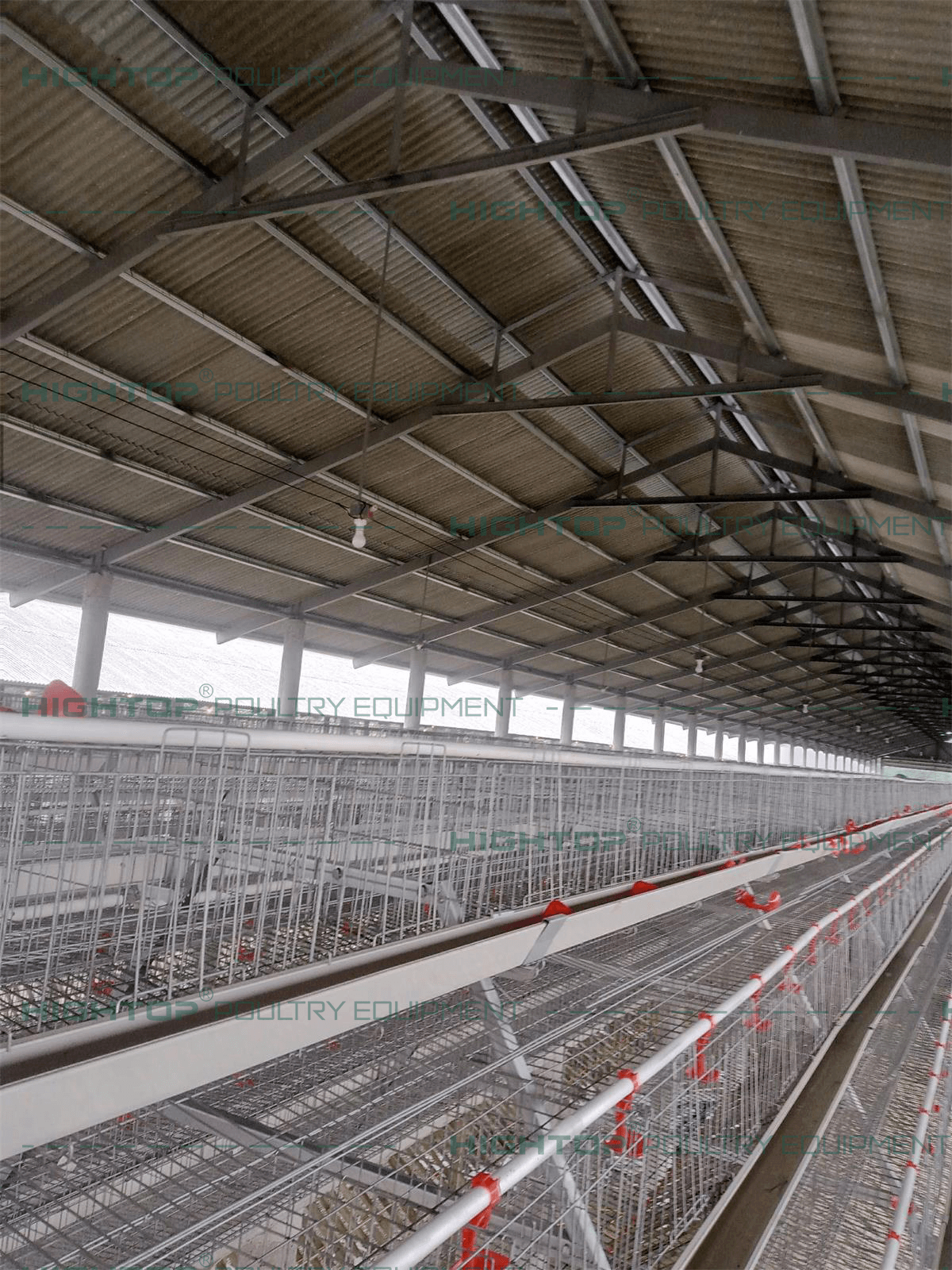

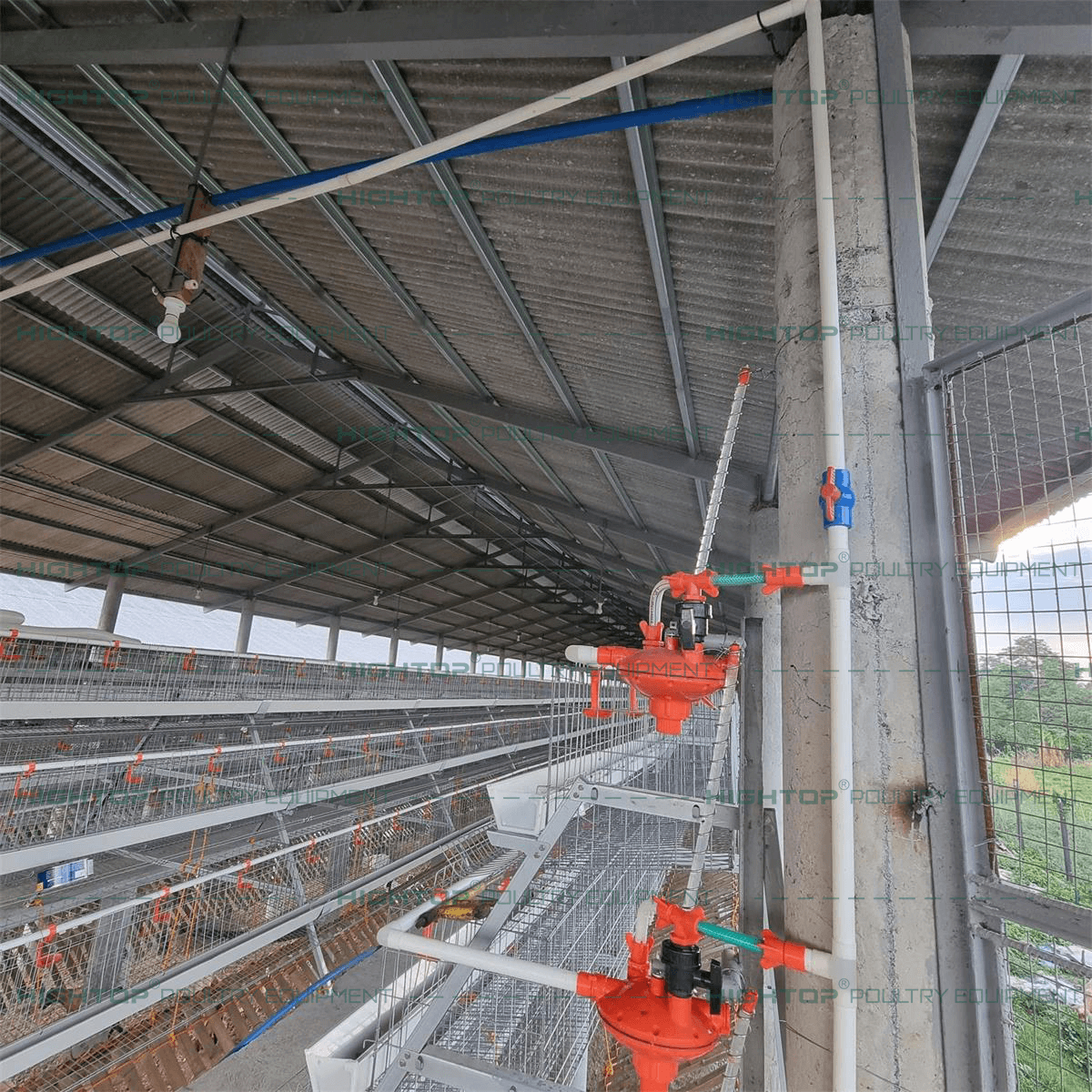

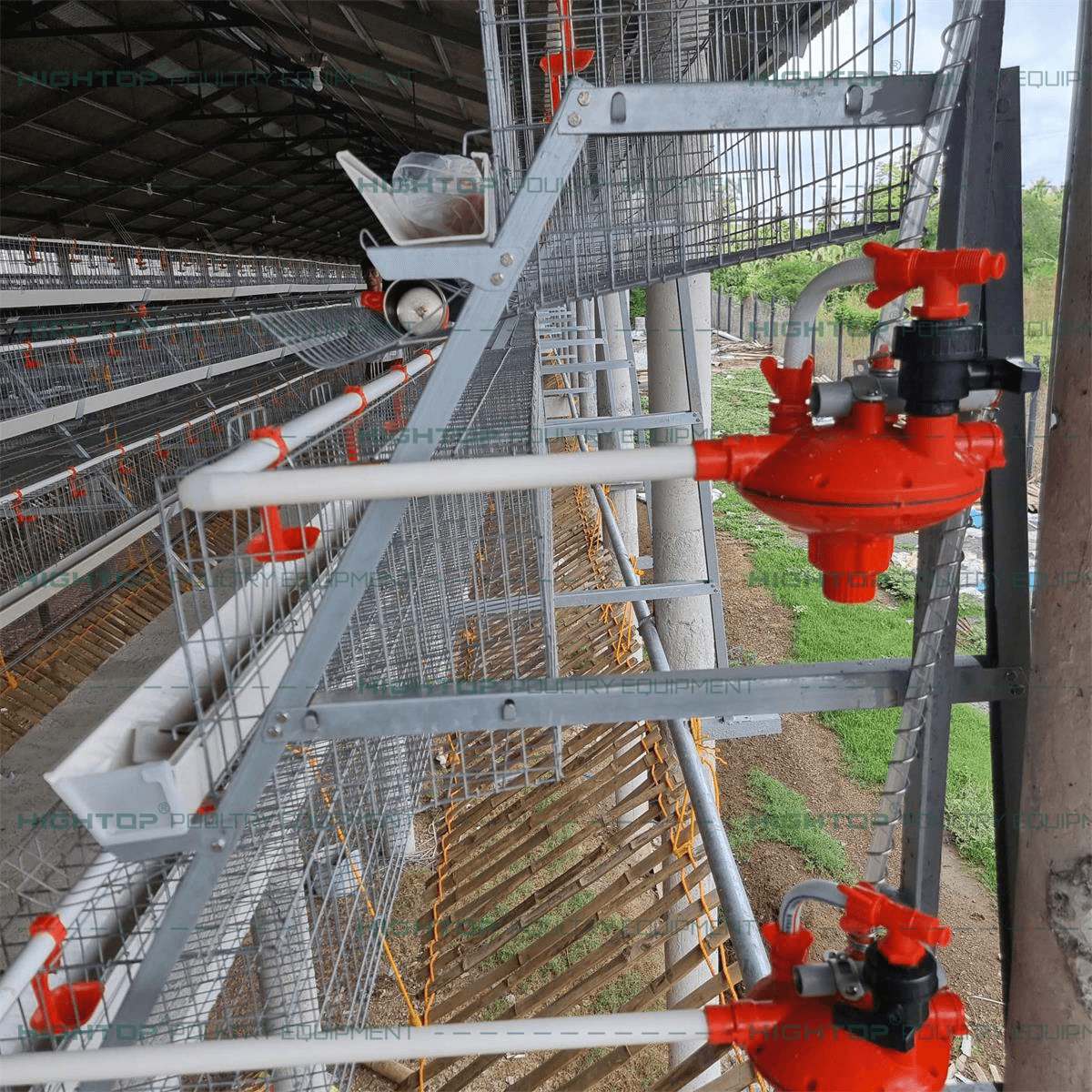

Secondly, in response to the unreasonable design of the chicken cage frame purchased by the customer for the second time, we adopted a customized cage frame solution. we achieved complete non-overlapping, no problem with chicken manure falling on the cage, and better ventilation in large spaces. Limited reduction of ammonia production and reduced the disease rate of chickens.

We met the customer’s many requirements, and with the blessing of professional services, the customer finally chose our Hightop. Of course, we did not live up to the customer’s trust and received good reviews from the customer.

Hightop is a 20-year-old factory of chicken cages, providing a one-stop shop for poultry farming equipment, helping 5000+ poultry farm projects in 30 different countries. You can trust us to design a customized solution for you based on your situation.